Core Guide to Paint Booth Walls and its Types

In the world of automotive refinishing, the one key element that always acts as a main picture is the Paint Booth. Take a tour about the Paint Booth Walls which may help you choose the best Spray Booth Walls based on your preferences.

A Paint Spray Booth or a Spray Booth often referred to as a Paint Booth, is a facility created especially for spraying activities that eliminates vapour and overspray generated during the spray application process. A spray booth is an enclosed or semi-enclosed specialist piece of equipment that is used for many purposes, including the spray painting of fabricated items. They are typically equipped with a source of filtered air and an exhaust system to vent the fumes of the evaporating solvents.

Non-combustible or limited combustible materials or assemblies of walls, doors and ceilings can be constructed securely and rigidly mounted or fastened. Smooth design is promised in the interior surface of the spray which when installed can prevent pockets that can trap residues and designed to expedite ventilation and cleaning.

All About Spray Booth Walls You Should Know

Paint booths are distinguished based on walls as single-skin or dual-skin walls. Both the single and dual-skin spray booth walls in terms of quality and cost offer advantages.

The single-skin panels are best for saving money without sacrificing quality which are also tough and robust. It provides a smooth inner surface in the external flanges making the inside walls of single-skin spray booth simple.

Dual-skin panels are suited more for a stronger, long-lasting paint booth which provides a smooth fit and finish. To keep hot air inside the cabin, they are insulated which helps in noise reduction and also keeps the heat outside the spray bottle.

The white walls increases the reflectivity of the lights which while painting makes it easier to see. These White pre-coated walls are available as options in Single-skin booths but are common in Dual-skin booths.

Types of Spray Booth Wall panels

PUF Panel

EPS panel

Rockwool Panel

PUF (PU) Panel

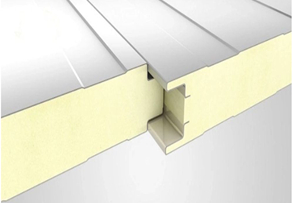

PUF (PU) Panel is a kind of sandwich panel with the core made up of Polyurethane, which is placed between two metal sheets. These panels have high thermal insulation properties – an attribute which makes them immensely useful.

Rockwool (Mineral oil) Panel

A thermal insulation material that many contractors use for walls, floors, roofs, attics, pipes, and ducting is the Rockwool (Mineral oil) Panel. These can fill most wall cavities, leaving virtually no voids. It is also used as spray-on fireproofing material.

EPS (Thermocol) Panel

EPS Cement Sandwich Panel is a lightweight energy saving wall material .it uses cement calcium silicate or reinforced calcium silicate board as face panel that is filled with cement, Expanded Polystyrene (EPS) foam particles, and as core material forming by one time compound.

ATS ELGI Offerings

In the segment of Paint Booth Walls, ATS ELGI uses Dual-Skin Insulated, Pre coated PUF Panels with Tongue and Groove locking mechanism for better sealing.

Benefits of using PUF Panels

- High structural durability and longevity

- Sturdiness

- Pre-engineered for precise dimension and accuracy

- Modular in nature

- Easy to dismantle and transport from one place to another as required

- Quick on-site installation

- Energy saving due to thermal insulation

- Environmentally friendly

- Light weight and Durable

- Weather resistance

- Versatility

- All-weather proof

Elevate the Performance with Paint Booth Walls

As we wrap up our exploration of paint booth walls, it is understood that these surfaces plays a vital role in achieving great results in various industries. Get in touch with us to know more about our products and services. You can also visit us at www.ats-elgi.com to explore more about the garage equipment’s in detail.